I was in need of a bit of retail therapy last week so popped into my local fabric shop for a bit of window shopping on different yarns and some kit-gazing. Kit-gazing is what I call it when I just go in and check out what cross stitch kits are available and which ones I would like to do next. (I don't buy any T, just look, honest).

Anyway, there I was head down in the bargain bucket full to bursting with cross stitch kits, when I overheard a conversation between two women standing next to me. They were also looking at the cross stitch kits and were awe struck at some of the beautifully designed and detailed kits that are available these days. The main problem they had though was having never done counted cross stitch before, they wouldn’t know how or where to start.

Oh, I thought, that’s not good. Now, I’ve been cross stitching for years, so it never occurred to me that to anyone one who doesn’t know how, cross stitch kits, especially counted cross stitch kits, can be a bit daunting and can look a bit too intricate and complicated. As I explained to the women in the fabric shop, it’s really very simple.

As the name suggests this kind of cross stitch is counted. The fabric is plain.

The stitches are positioned by counting the squares on the chart and matching these to the fabric. The kit will tell you how many squares on the chart equal one stitch. It’s usually one square equals one stitch. The kit will also say how many strands of cotton to use for each stitch.

Stranded cotton, also known as embroidery floss can be split into single strands. The number of strands used will alter the thickness of the stitch. Most kits I have worked on ask you to use two strands for the cross stitches with other stitches such as back stitch using just one strand. Back stitch is used to define edges within a design. Keeping the back stitch finer or thiner than the chunkier cross stitches helps to make them stand out.

A cross stitch is literally a cross or an X shape. It's normally worked on an evenweave fabric like aida or linen. Evenweave means there are the same number of fabric threads going up and down as there are across.

Basically, a cross stitch is - up from the back in one hole (say, bottom left), down in the opposite hole (top right). Up again from the back in the top left hole and then down in the bottom right. This makes one individual cross.

It doesn't really matter how you form your stitches. There is more than one way to make an X. The only thing you need to bear in mind is that the top strand of every cross stitch must go in the same direction all the time. Doesn’t matter which way but it must always be the same way.

You can do whole rows by doing half of the stitch and then coming back over them with the top strand.

If you finish a row of stitches and the next one is a few rows away – don’t stretch across the back of the fabric to reach it. It will make the back messy and wastes thread. Always cast off and re-cast on at the new place if you have to jump more than two squares.

Don’t use knots. Knots can cause little bumps in your work. When casting on, if it’s the very first stitch - catch the end of the thread on the back of the fabric into the loop of the stitch as you pull the thread through the holes.

If some stitches have already been made, pass the thread under a few of the nearby stitches on the back of the fabric. Cast off in the same way, by passing the thread under nearby stitches on the back.

I always use a highlighter on the chart to tick off the cross stitches that I have completed. This not only helps with counting but also, as I have a memory like a sieve, it helps me remember where I am.

Anyway, there I was head down in the bargain bucket full to bursting with cross stitch kits, when I overheard a conversation between two women standing next to me. They were also looking at the cross stitch kits and were awe struck at some of the beautifully designed and detailed kits that are available these days. The main problem they had though was having never done counted cross stitch before, they wouldn’t know how or where to start.

Oh, I thought, that’s not good. Now, I’ve been cross stitching for years, so it never occurred to me that to anyone one who doesn’t know how, cross stitch kits, especially counted cross stitch kits, can be a bit daunting and can look a bit too intricate and complicated. As I explained to the women in the fabric shop, it’s really very simple.

As the name suggests this kind of cross stitch is counted. The fabric is plain.

The stitches are positioned by counting the squares on the chart and matching these to the fabric. The kit will tell you how many squares on the chart equal one stitch. It’s usually one square equals one stitch. The kit will also say how many strands of cotton to use for each stitch.

Stranded cotton, also known as embroidery floss can be split into single strands. The number of strands used will alter the thickness of the stitch. Most kits I have worked on ask you to use two strands for the cross stitches with other stitches such as back stitch using just one strand. Back stitch is used to define edges within a design. Keeping the back stitch finer or thiner than the chunkier cross stitches helps to make them stand out.

To centre the design, fold your fabric in half and then in half again. Pinch the middle. Open it out. Where the folds cross is the centre. Check the chart. It should have arrows on it. Where the arrows meet in the middle is the centre of the chart. This stitch needs to be in the centre of the fabric.

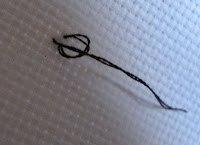

I tend to start here and work outwards. So with the red design below, I started with the top cross and worked my way downwards from there. A cross stitch is literally a cross or an X shape. It's normally worked on an evenweave fabric like aida or linen. Evenweave means there are the same number of fabric threads going up and down as there are across.

Basically, a cross stitch is - up from the back in one hole (say, bottom left), down in the opposite hole (top right). Up again from the back in the top left hole and then down in the bottom right. This makes one individual cross.

It doesn't really matter how you form your stitches. There is more than one way to make an X. The only thing you need to bear in mind is that the top strand of every cross stitch must go in the same direction all the time. Doesn’t matter which way but it must always be the same way.

You can do whole rows by doing half of the stitch and then coming back over them with the top strand.

If you finish a row of stitches and the next one is a few rows away – don’t stretch across the back of the fabric to reach it. It will make the back messy and wastes thread. Always cast off and re-cast on at the new place if you have to jump more than two squares.

Don’t use knots. Knots can cause little bumps in your work. When casting on, if it’s the very first stitch - catch the end of the thread on the back of the fabric into the loop of the stitch as you pull the thread through the holes.

If some stitches have already been made, pass the thread under a few of the nearby stitches on the back of the fabric. Cast off in the same way, by passing the thread under nearby stitches on the back.

I always use a highlighter on the chart to tick off the cross stitches that I have completed. This not only helps with counting but also, as I have a memory like a sieve, it helps me remember where I am.

It also has an unexpected advantage of showing T that I am working on all of my UFO's - not just buying cross stitch kits for my stash. (As if I'd do that....Te he..)

Bye for Now

Olly

Comments

Post a Comment